December 10, 2024

Automate frame section creation in SAP2000 using Python and Excel

by Luis Maldonado de la Torre

What if you could automate this process? With the SAP2000 API and Python, you can transform a traditional workflow into an efficient and seamless one. It is straightforward to generate and define load patterns, combinations, and mass sources through code. Additionally, automation stands out in tasks such as assigning restraints to nodes, generating elements like beams, columns, and slabs, and distributing uniform or point loads.

In this blog, we'll explore how to use Python to create frame sections for SAP2000 automatically by reading section properties from an Excel file.

By the end, you will have an automated workflow that reduces manual effort and enhances your productivity.

Getting Started

Using the SAP2000 API, we connect to an active instance of the program and define material properties, cross-sectional geometries, and reinforcement details for frames. We'll start with some simple examples of creating individual beam and column sections, and later show how to automate the entire process using data from Excel.

1. Import Necessary Libraries

To begin, we need to import the required libraries: comtypes to connect with SAP2000 and pandas to read Excel data:

1from comtypes.client import GetActiveObject 2import pandas as pd

2. Connect to SAP2000

Ensure that SAP2000 is open, then connect to the active instance using the following code:

1try:

2SapModel = GetActiveObject("CSI.SAP2000.API.SapObject").SapModel

3print("Successfully connected to SAP2000.")

4except Exception as e:

5print("Failed to connect to SAP2000. Ensure the program is open.")

6print(f"Error details: {e}") 3. Create Materials

In this section, we will first learn how to use the SAP2000 API functions to define materials step by step.

Once we understand the process, we will move on to a more efficient approach by reading data from an Excel file. This allows us to create multiple materials automatically.

Reinforcement Steel

We must indicate the units with which we will work, using the following code we will define the work units of Kg, m and C, which have the number 8 as a label:

1kgf_m_C = 8 2SapModel.SetPresentUnits(kgf_m_C)

Next, we create the material properties this involves setting material type, modulus of elasticity, Poisson's ratio, thermal coefficient, and strength properties for the reinforcement steel grade 60 with a yield strength of 4200 kg/cm² and a modulus of elasticity of 2.0E10 kg/cm².

1material_id = 6 # Rebar 2 3SapModel.PropMaterial.SetMaterial( 4 'fy=4200', # Material name 5 material_id # Material Type ID 6) 7 8SapModel.PropMaterial.SetMPIsotropic( 9 'fy=4200', 10 2.0E10, # Modulus of elasticity 11 0.2, # Poisson's ratio 12 9.90E-06 # Thermal coefficient 13) 14 15SapModel.PropMaterial.SetWeightAndMass( 16 'fy=4200', 17 1, # 1: Weight, 2: Mass per unit volume 18 7850 # Value 19) 20 21SapModel.PropMaterial.SetORebar( 22 'fy=4200', 23 42000000, # Yield strength 24 63000000, # Tensile strength 25 46000000, # Expected Yield strength 26 69000000, # Expected Tensile strength 27 2, # Stress-strain curve type 28 2, # Stress-strain curve type - Hysteretic 29 0.02, # Strain at Hardening 30 0.1, # Strain Ultimate 31 False # True: Uses Caltrans controlling strain values 32)

Read Excel File "SectionData.xlsx"

We then read section properties from an Excel file that contains all necessary details about the materials, dimensions, and types of frames (beams or columns):

1df = pd.read_excel("SectionData.xlsx")

If you would like to use the same Excel sheet as is used in this blog, feel free to download it here.

It is important to know the units of the data that Excel contains.

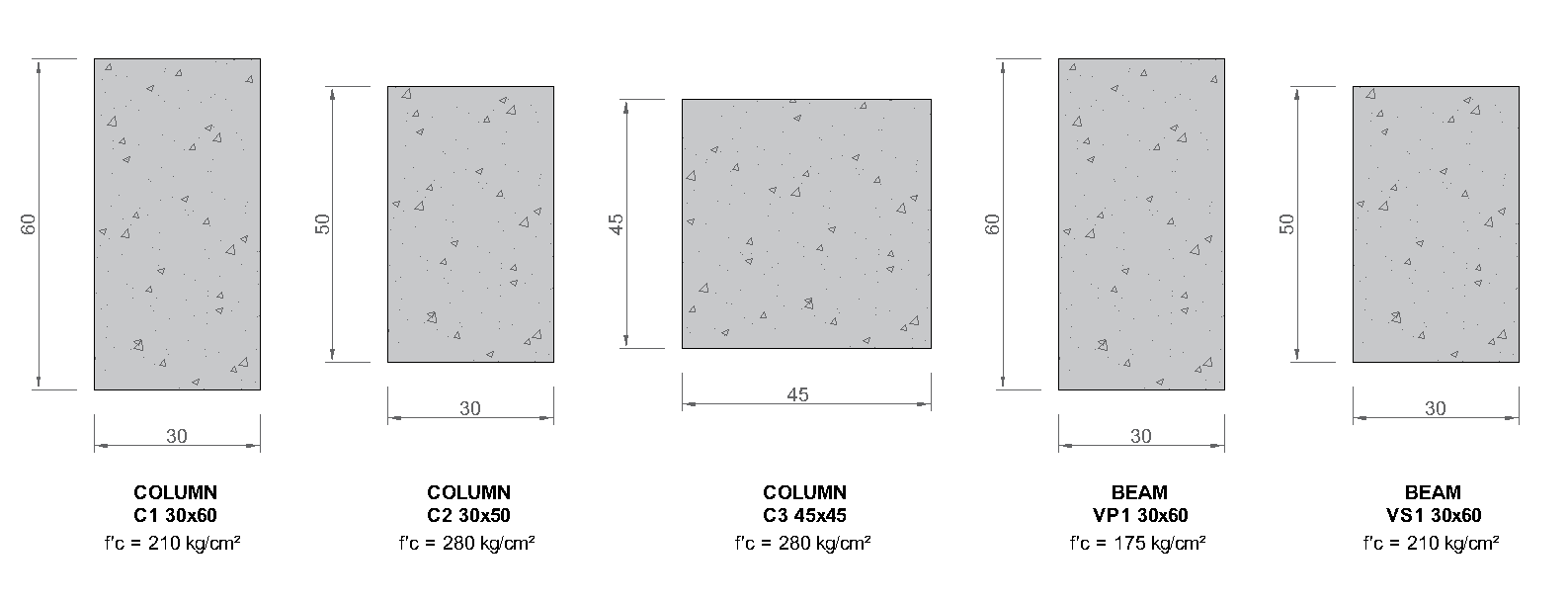

The column ID is the element label, b and h are the base and height in centimeters, respectively, and fc is the concrete compressive strength in kg/cm²:

| Type | ID | b | h | fc |

|---|---|---|---|---|

| COL | C1 | 30 | 60 | 210 |

| COL | C2 | 30 | 50 | 280 |

| COL | C3 | 30 | 60 | 175 |

| BEAM | VP1 | 30 | 60 | 210 |

| BEAM | VS1 | 30 | 50 | 280 |

| BEAM | VB1 | 30 | 60 | 210 |

Create Concrete Material from Excel Data

After reading the Excel file, we will identify the unique compressive strength (f'c) values that will be assigned to the frame element sections. Then, we will create a dictionary with the names that each material will have.

1fc = df["fc"].unique()

2name_material = {fc_i: f'fc={fc_i}' for fc_i in fc} Next, we will start creating the concrete materials, assigning their properties, such as modulus of elasticity and strength, according to specific f'c values.

1for fc_i in fc: 2 material_id = 2 # Concrete 3 material = name_material.get(fc_i) 4 SapModel.PropMaterial.SetMaterial(material, material_id) 5 E = 15100 * (fc_i ** 0.5) * 10000 # (kgf/m²) 6 SapModel.PropMaterial.SetMPIsotropic(material, E, 0.25, 9.90E-06) 7 SapModel.PropMaterial.SetWeightAndMass(material, 1, 2400) 8 SapModel.PropMaterial.SetOConcrete(material, 2800000, False, 0, 1, 2, 0.0022, 0.0052)

4. Creating Beam and Column Sections

Before we move on to automation, let's look at some examples of how to create sections. We'll do an example of a beam and a column to demonstrate the basic workflow.

Example:

We define a beam section (BEAM_1) with the dimensions 0.6 m depth and 0.3 m width and a column section (COLUMN_1) with dimensions 0.45 m by 0.45 m, using the SetRectangle method.

Let's not forget that we have defined our work unit in meters and it is important to note that the material fc=280 must exist.

1# Define rectangular section properties for a beam 2SapModel.PropFrame.SetRectangle('BEAM_1', # Section name 3 'fc=280', # Existing material name 4 0.6, # Depth 5 0.3) # Width 6# Define rectangular section properties for a column 7SapModel.PropFrame.SetRectangle('COLUMN_1', 'fc=280', 0.25, 0.50) 8

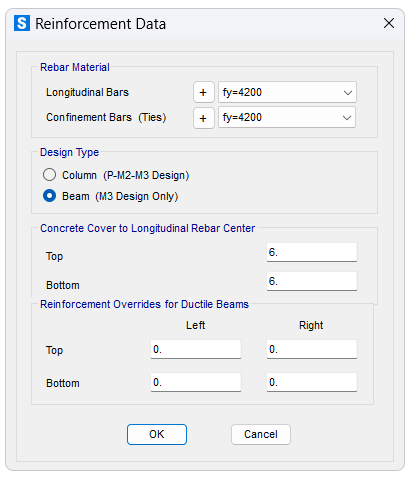

Creating a Beam Section

SetRebarBeam adds longitudinal and transverse reinforcement.

1# Define rebar properties for the beam 2SapModel.PropFrame.SetRebarBeam('BEAM_1', 3 # Section name 4 'fy=4200', # Longitudinal rebar material 5 6 'fy=4200', # Transverse rebar material 7 8 0.06, # Top cover 9 10 0.06, # Bottom cover 11 12 0, # Top left area 13 14 0, # Top right area 15 16 0 , # Bottom left area 17 18 0) # Bottom right area 19

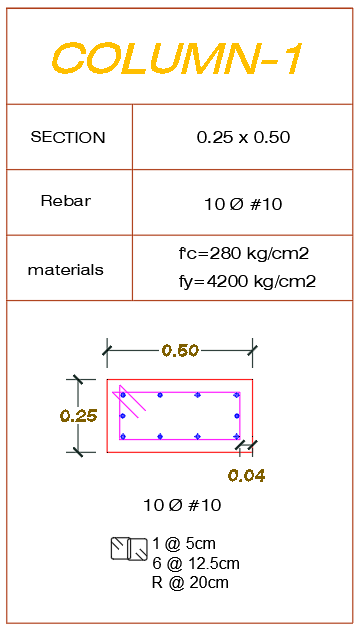

Creating a Column Section

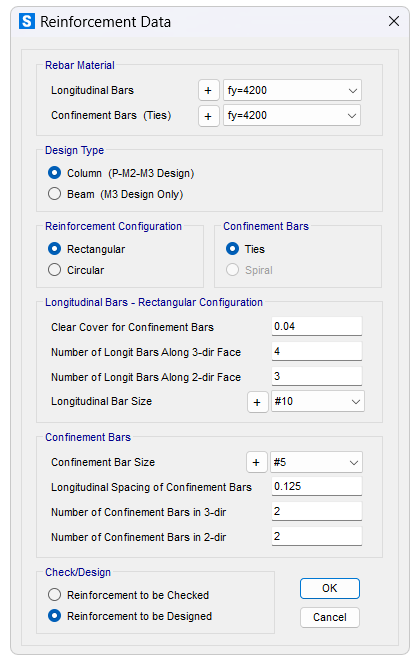

Here, we also specify the rebar arrangement using SetRebarColumn, including longitudinal and Confinement reinforcement properties.

For this, we will work with the data provided in the plan. The column section will measure 0.25m x 0.50m, with 10 longitudinal reinforcement bars of #10 diameter. The concrete's compressive strength will be 280 kg/cm², and the reinforcement steel's yield strength will be 4200 kg/cm². The bars and stirrups will be distributed as indicated in the plan.

1# Define rebar properties for the column 2SapModel.PropFrame.SetRebarColumn('COLUMN_1', # Section name 3 4 'fy=4200', # Longitudinal rebar material 5 6 'fy=4200', # Transverse rebar material 7 8 1, # Rectangular pattern 9 10 1, # Confinement type (ties) 11 12 0.04, # Cover 13 14 0, # Applies only to circular columns 15 16 4, # Number of bars along local axis 3 17 18 3, # Number of bars along local axis 2 19 20 '#10', # Longitudinal bar size 21 22 '#5', # Confinement bar size 23 24 0.125, # Tie spacing (m) 25 26 2, # Number of ties along axis 2 27 28 2, # Number of ties along axis 3 29 30 True) # To be designed 31

Automate Section Creation for Beams and Columns Using Excel Data

First we must change our work units, because the Excel sheet contains information in units of kg and cm

1kg_cm_C = 14 2SapModel.SetPresentUnits(kg_cm_C)

Finally, we automate the process for creating beam and column sections using the data from the Excel file. The script iterates through each row of the DataFrame and creates the appropriate section in SAP2000:

1for _, row in df.iterrows():

2 material = name_material.get(row["fc"])

3 name_section = f'{row["ID"]}-{row["b"]}x{row["h"]}'

4 SapModel.PropFrame.SetRectangle(name_section, material, row["h"], row["b"])

5 if row["Type"] == "COL":

6 SapModel.PropFrame.SetRebarColumn(name_section, 'fy=4200', 'fy=4200', 1, 1, 4, 0, 4, 5, "#5", "#3", 12.5, 4, 2, True)

7 elif row["Type"] == "BEAM":

8 SapModel.PropFrame.SetRebarBeam(name_section, 'fy=4200', 'fy=4200', 6, 6, 0, 0, 0, 0)

9 print(f'{name_section} {material} has been created') 5. Final Code

For your convenience, the complete code can be found here:

1from comtypes.client import GetActiveObject

2import pandas as pd

3

4try:

5 SapModel = GetActiveObject("CSI.SAP2000.API.SapObject").SapModel

6 print("Successfully connected to SAP2000.")

7except Exception as e:

8 print("Failed to connect to SAP2000. Ensure the program is open.")

9 print(f"Error details: {e}")

10

11# Set units to kgf, m, C

12kgf_m_C = 8

13SapModel.SetPresentUnits(kgf_m_C)

14

15# Set material properties for reinforcement steel

16material_id = 6 # Rebar

17SapModel.PropMaterial.SetMaterial('fy=4200', material_id)

18SapModel.PropMaterial.SetMPIsotropic('fy=4200', 2.0E10, 0.2, 9.90E-06)

19SapModel.PropMaterial.SetWeightAndMass('fy=4200', 1, 7850)

20SapModel.PropMaterial.SetORebar('fy=4200', 42000000, 63000000, 46000000, 69000000, 2, 2, 0.02, 0.1, False)

21

22# Read data from Excel

23df = pd.read_excel("SectionData.xlsx")

24

25# Create concrete materials from Excel data

26fc = df["fc"].unique()

27name_material = {fc_i: f'fc={fc_i}' for fc_i in fc}

28for fc_i in fc:

29 material_id = 2 # Concrete

30 material = name_material.get(fc_i)

31 SapModel.PropMaterial.SetMaterial(material, material_id)

32 E = 15100 * (fc_i ** 0.5) * 10000 # (kgf/m²)

33 SapModel.PropMaterial.SetMPIsotropic(material, E, 0.25, 9.90E-06)

34 SapModel.PropMaterial.SetWeightAndMass(material, 1, 2400)

35 SapModel.PropMaterial.SetOConcrete(material, 2800000, False, 0, 1, 2, 0.0022, 0.0052)

36

37# Change units to kg, cm, C

38kg_cm_C = 14

39SapModel.SetPresentUnits(kg_cm_C)

40

41# Create sections from Excel data

42for _, row in df.iterrows():

43 material = name_material.get(row["fc"])

44 name_section = f'{row["ID"]}-{row["b"]}x{row["h"]}'

45 SapModel.PropFrame.SetRectangle(name_section, material, row["h"], row["b"])

46 if row["Type"] == "COL":

47 SapModel.PropFrame.SetRebarColumn(name_section, 'fy=4200', 'fy=4200', 1, 1, 4, 0, 4, 5, "#5", "#3", 12.5, 4, 2, True)

48 elif row["Type"] == "BEAM":

49 SapModel.PropFrame.SetRebarBeam(name_section, 'fy=4200', 'fy=4200', 6, 6, 0, 0, 0, 0)

50 print(f'{name_section} {material} has been created')Each beam and column section is created automatically, saving a significant amount of time compared to manual input.

Conclusion

The SAP2000 API combined with Python opens the door to streamlined, efficient workflows in structural engineering. From defining materials and creating sections to automating repetitive tasks, these tools help reduce errors, improve consistency, and save valuable time when managing complex projects.

But this is just the beginning—Python's versatility allows you to enhance every aspect of your engineering processes. Ready to take your automation skills further? Explore how you can create intuitive and shareable web applications to make your workflows even more powerful. Start automation and unlock the full potential of modern structural engineering today!