Sign In

October 03, 2022

Arcadis accelerates digital transformation with VIKTOR

Download the White Paper and get INSPIRED

Learn about trends in digital transformation and how they affect the engineering and construction industry.

More efficient solutions

For years, Arcadis relied on a manual process to design underwater concrete floors. Engineers used a combination of validated Excel sheets and various off-the-shelf software to perform calculations. While this system worked, it came with significant challenges: coordinating between different departments was time-consuming, and the process was rigid, only allowing for the calculation of specific designs under fixed conditions. This made it difficult to explore different scenarios or optimize designs for cost and performance, slowing down project timelines.

Recognizing the need for a more efficient solution, Arcadis set out to automate these calculations. They turned to the VIKTOR platform, where they developed a custom application that integrated their existing Excel-based processes. This new tool allowed engineers to quickly experiment with different input parameters, exploring a variety of design options with ease. By automating these calculations, they drastically reduced the time spent on coordination and improved the flexibility of their designs.

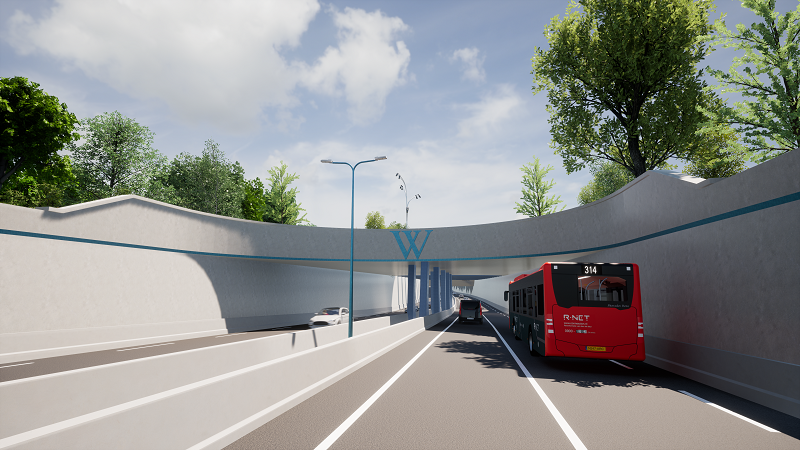

What began as a pilot for underwater concrete floors soon evolved into a broader solution. The success of this initial tool paved the way for additional applications, helping Arcadis tackle other engineering challenges like the design of submersible tunnels, noise barriers, and underpasses.

© Arcadis Architecten (Tom Kramer) commissioned by Province of North-Holland.

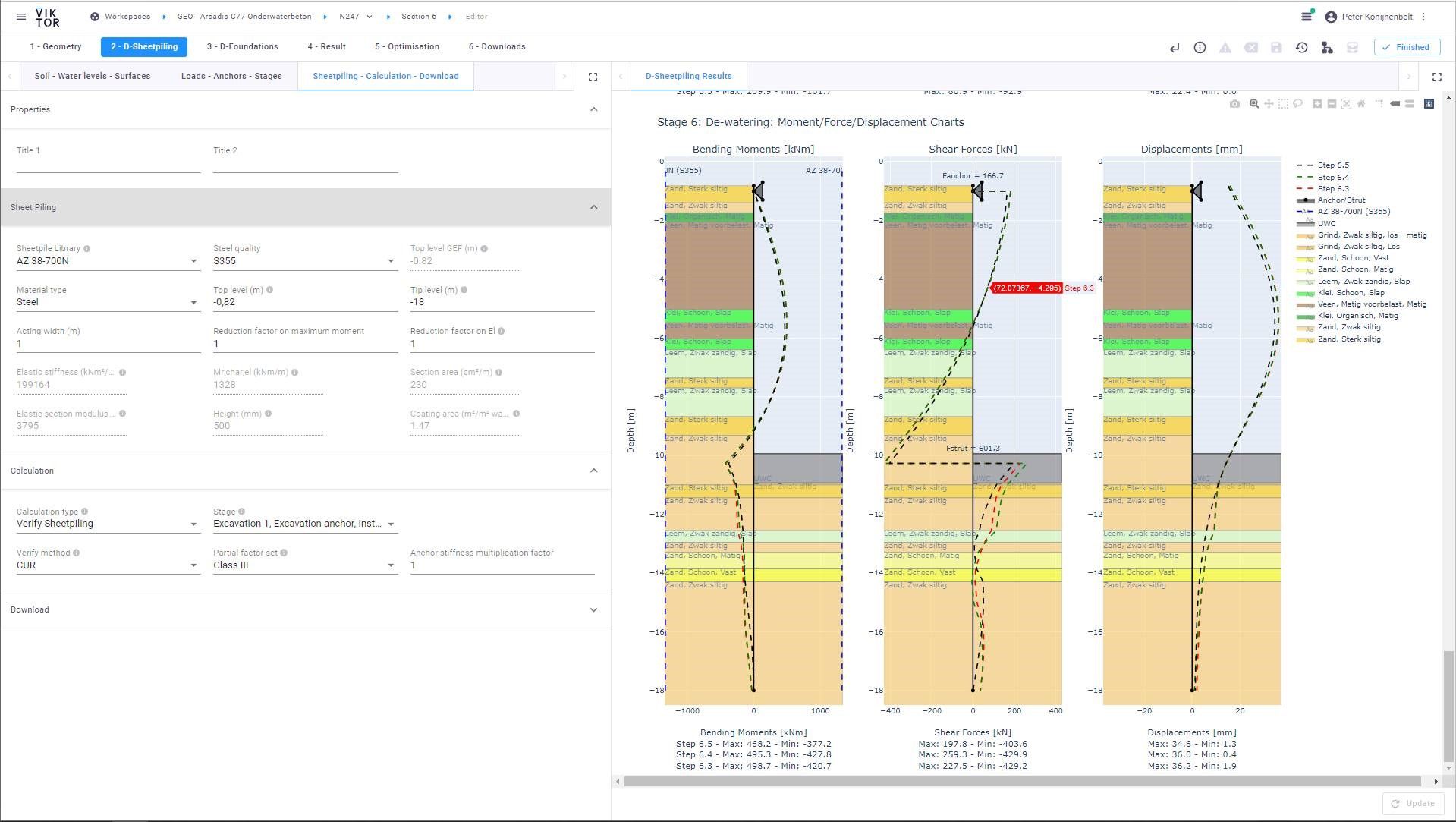

Integrating software to streamline processes

Arcadis expanded its initial application by integrating additional software tools, like Deltares, SCIA Engineer, and IDEA StatiCa, to create a comprehensive construction pit design tool. This tool connects Deltares' D-Sheetpiling and D-Foundations software, allowing for the automated calculation of tensile piles, sheet piles, and soil layer analysis via CPT uploads. What began as a tool for underwater concrete floors grew into a full-featured application that automates the design of the entire construction pit, including cost estimation based on the generated designs.

“The tool was first created for underwater concrete calculations, but in the end, it became a total construction pit design tool. We can now fully calculate the underwater concrete, pile foundations, and the sheet piles of the construction pit itself.” – Mark van Esseveld, Project Manager at Arcadis

By extracting data from D-Sheetpiling and processing pile reactions through Excel and D-Foundations, the tool automates multiple design scenarios. This integration streamlines the design process, reducing manual input and allowing engineers to focus on optimization.

“As an engineer, you use a lot of programs for different construction types. VIKTOR allows these programs to communicate with each other, which reduces errors and speeds up the design process.” – Peter Konijnenbelt, Senior Designer at Arcadis

Excavation results from D-Sheetpiling

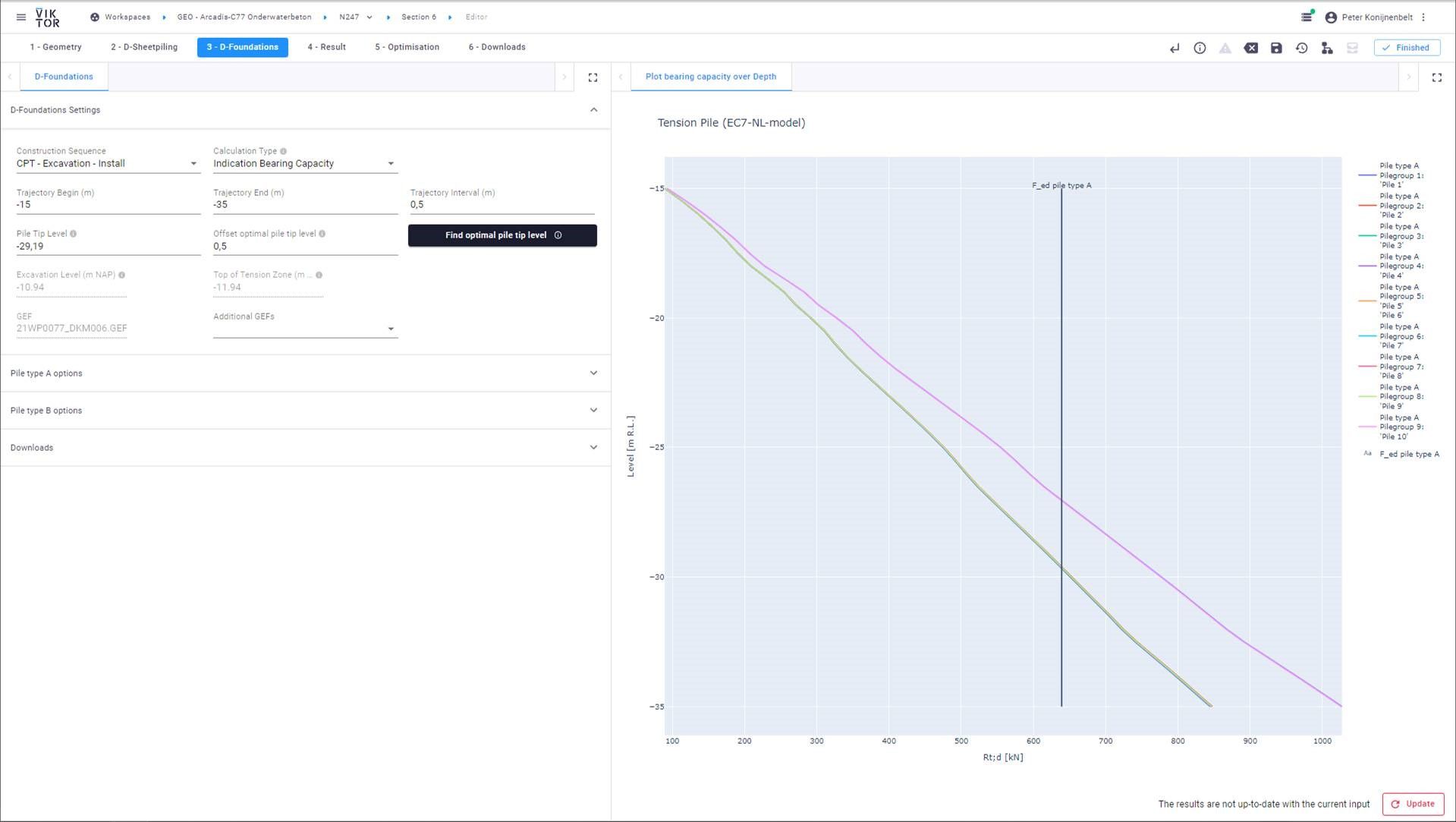

Optimal pile tip levels from D-Foundations

Optimal design based on costs

Arcadis added a cost optimization component to the tool, automating the calculation and evaluation of designs based on cost parameters such as the amount of steel used and installation costs. Each design is matched with a price, allowing Arcadis - or the client - to select the most cost-effective solution for the project.

“We provide the client with full transparency on design options based on a range of parameters. This allows them to select the optimal design based on costs and other criteria.” – Mark van Esseveld, Project Manager at Arcadis

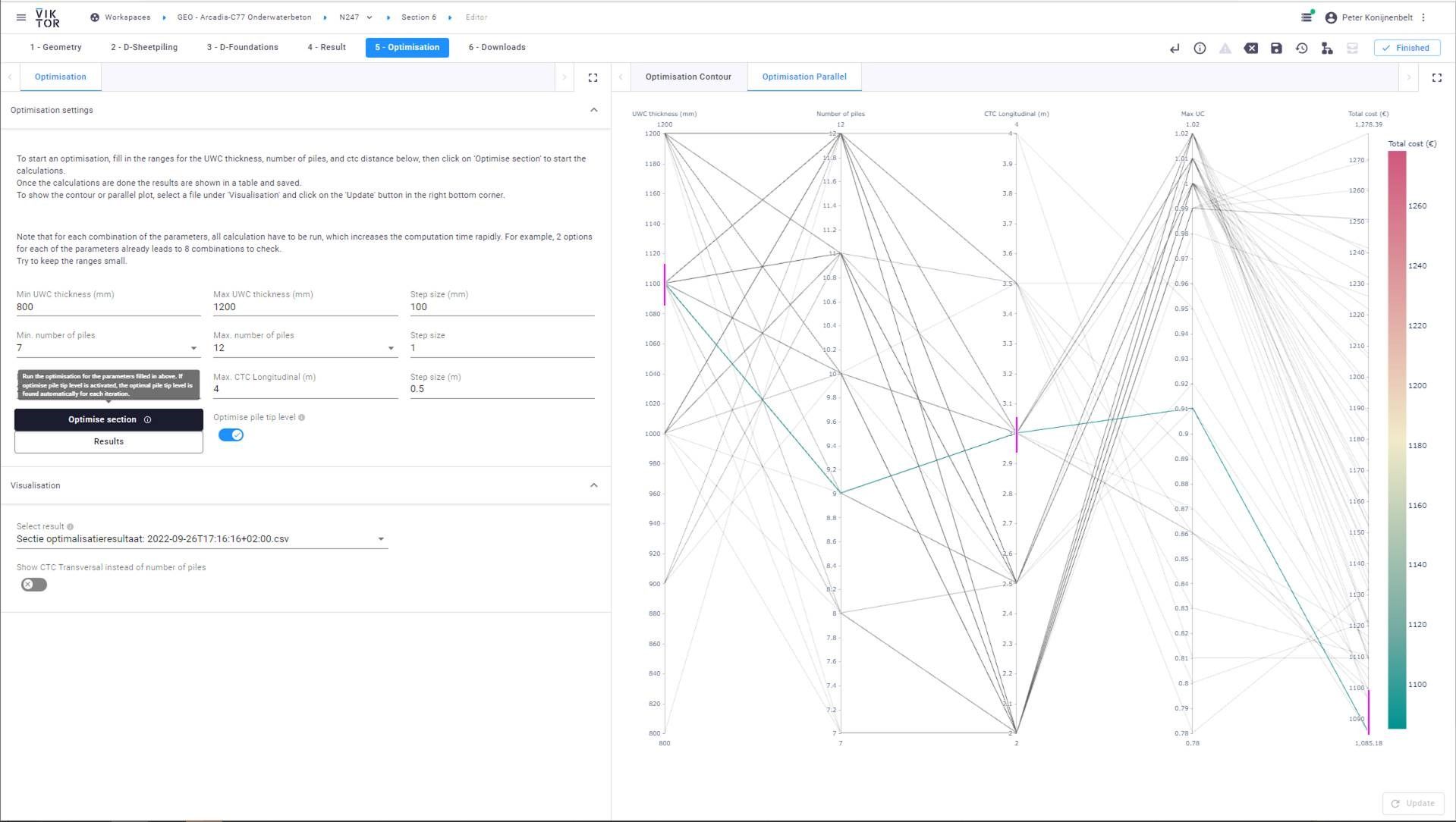

Presentation of the optimization results via a parallel coordinates plot

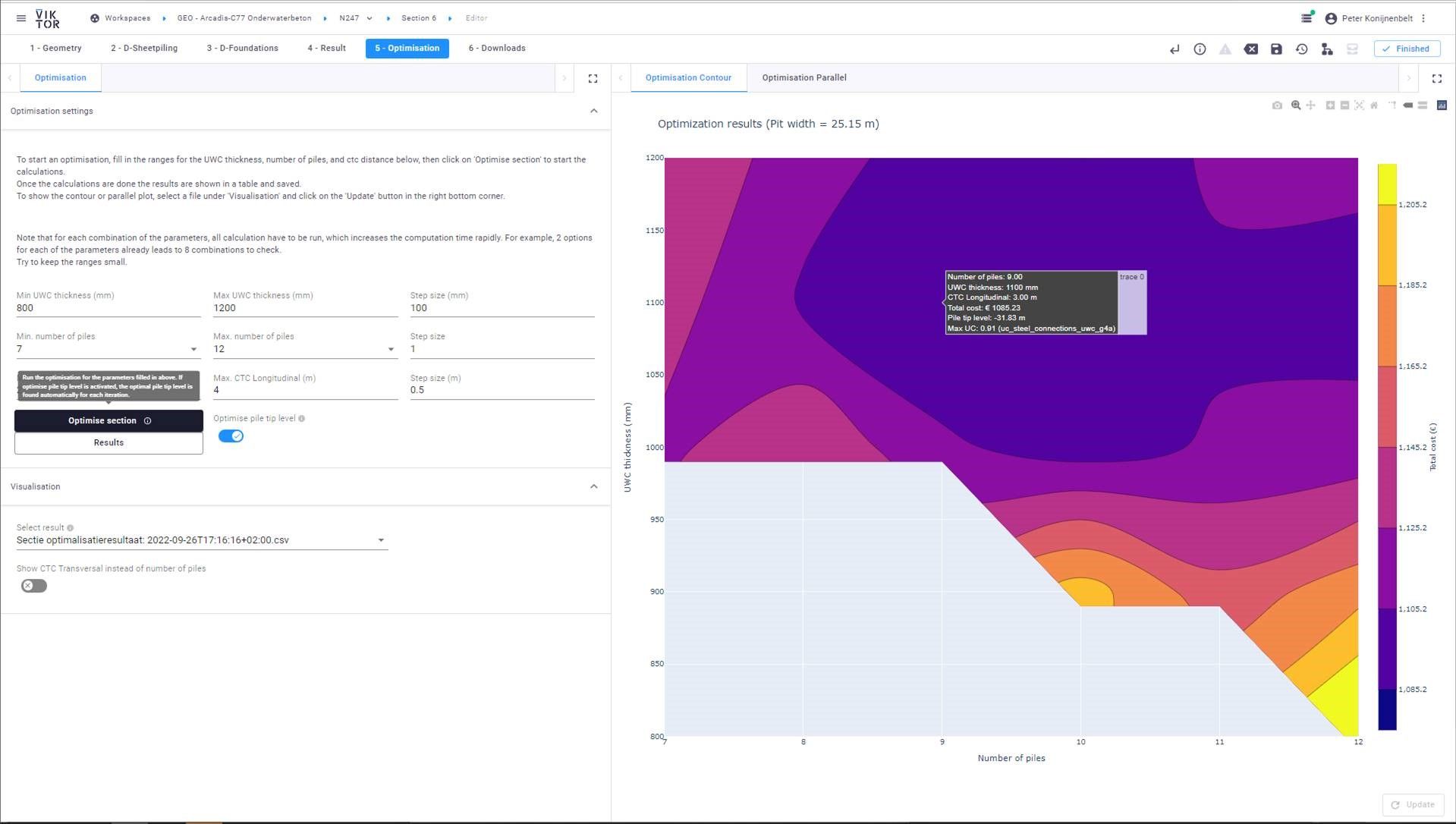

Alternative representation of the optimization results via a contour plot

Interdisciplinary collaboration made possible

When asked about the most significant benefit of the VIKTOR application, Arcadis points to improved efficiency. The tool enables a single engineer to handle tasks that previously required collaboration between a designer and a geotechnical expert, saving time while delivering higher-quality results. This efficiency allows Arcadis to explore more design options at the same cost, providing greater value to clients.

“We can do more in less time, optimizing the design as we go. The process is smoother, and the results are more accurate, which is a big advantage for our clients.” – Mark van Esseveld, Project Manager at Arcadis

By automating steps and integrating various software tools, the application reduces manual data transfer, minimizes errors, and speeds up the design process. Specialists still review results, but the automation allows them to focus on validation rather than repetitive calculations.

Accessible automation for non-experts

Thanks to its user-friendly interface, the construction pit tool is widely used within Arcadis by divisions such as Construction, Geotechnics, and Costs. The VIKTOR platform’s intuitive design guides users through the process, making it easy for non-experts to utilize the tool and participate in the design process.

“The VIKTOR platform is highly user-friendly, even for colleagues who aren’t programmers. It simplifies the design process, generates clear outputs, and accelerates the calculation process, improving both speed and quality.” – Mark van Esseveld, Project Manager at Arcadis

Scaling innovation

The success of the construction pit tool has inspired further application development across Arcadis. The code developed for this tool is being reused to create similar applications for other divisions, such as the Buildings and Water division, demonstrating the scalability and adaptability of VIKTOR’s platform.

“We’re building a code library that makes it easier to develop new apps for future projects. This allows us to continuously expand our digital capabilities across the organization.” – Peter Konijnenbelt, Senior Designer at Arcadis