Accelerating energy transition with Mobriq

To decrease construction time for high-voltage substation foundations by 50%, Mobilis created an innovative system named Mobriq. Mobriq contributes to more efficient, circular, and sustainable construction processes by employing modular and reusable prefabricated beams. For example, projects like the 380kV high-voltage station for TenneT in Tilburg.

Hackathon

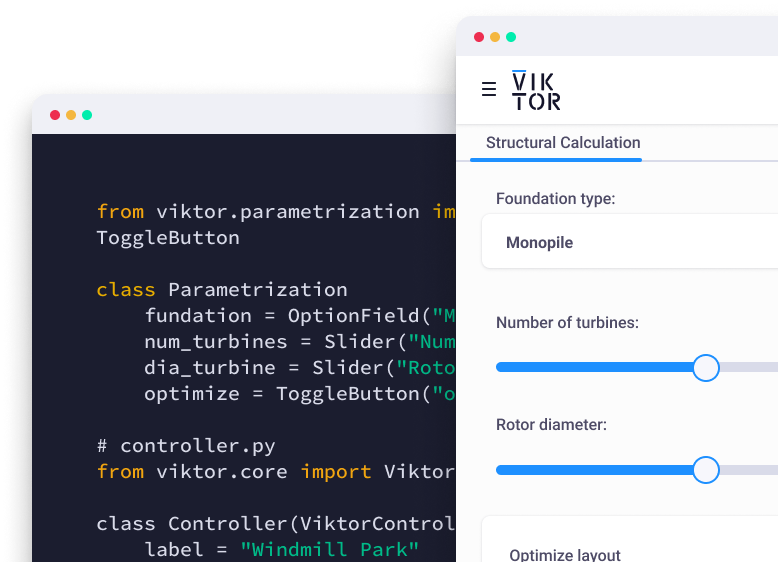

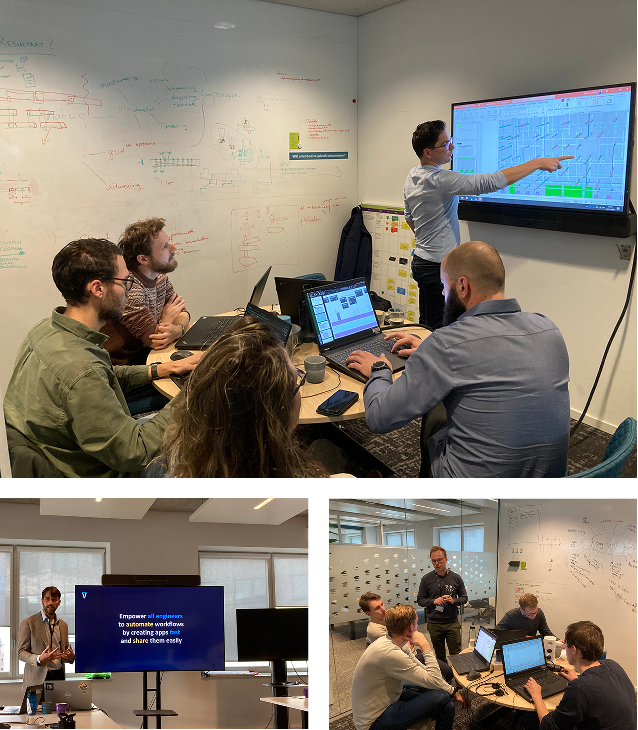

Mobilis is dedicated to driving innovation and improving efficiency in engineering workflows through digital solutions. Together with VIKTOR, they organized a hackathon to explore how automation can streamline repetitive tasks and allow engineers to focus on more impactful work, specifically for their TenneT Mobriq projects.

Some common challenges they wanted to tackle during the hackathon include:

-

Repetitive calculations: Engineers often spend significant time on repetitive tasks, such as generating beam and foundation designs.

-

Optimization: Improving material efficiency and minimizing (environmental) costs are critical for large-scale projects.

-

Time constraints: Rapidly generating accurate designs is essential to meet tight project timelines.

During the hackathon, multiple teams were brought together to brainstorm solutions to these challenges and built them as applications on the VIKTOR platform, using Python. Ultimately, three applications were created – but only one could be the winner.

"Automation is important in the industry because there's a lot of repetitive work. Our tasks can easily be programmed to automate, allowing you to focus on more specialized, technical aspects instead of spending all your time on repetitive calculations." – Jilles van der Werf, Constructor at Mobilis and hackathon attendee

Winning application

The standout app came from team “Plan B”, consisting of Richard Westerbeek (Contructor), Sebastiaan Schippers (Modeller), Jilles van der Werf (Constructor), and Arjan Roodnat (Work Planner).

Plan B’s High Voltage Station app automates the design of Mobriq components used to built high voltage stations from start to finish, integrating multiple software programs, like Revit, D-Foundations, IDEA StatiCa and RFEM. By inputting portal and component coordinates along with load data, the app generates a complete design, including:

-

Automated layouts for beams and foundations.

-

Optimized dimensions and reinforcements.

-

Comprehensive output with design plans, rebar drawings, and reports.

Considering these improvements, using the application promises significant time savings compared to following the traditional design process.

"In the energy transition, we see many stations being built. In all cases, the fundamentals are the same. Each project is only slightly different.” – Sebastiaan Schippers, Modeller at Mobilis

Partnership

At Mobilis, engineers and domain experts have been leveraging VIKTOR to build apps that automate engineering processes for several years. But VIKTOR is more than just a platform for app development—it’s a strategic partner in Mobilis’ automation journey. This hackathon highlights the strength of this collaboration.

Together, Mobilis and VIKTOR brought together technical experts, Python developers, and other interested participants who might not yet have the skills to create their own tools. The event showcased how even those with little to no Python experience can easily build tools to streamline their workflows and drive innovation.

"The partnership between Mobilis and VIKTOR shows how combining industry expertise with digital tools empowers engineers to innovate faster and smarter, as demonstrated during events like these.” – Wouter Riedijk, CSO at VIKTOR

What’s next?

The hackathon demonstrated the powerful synergy between engineering expertise and digital innovation. In just one day, teams used the VIKTOR platform to create promising solutions to common challenges in the energy transition. And this is only the beginning, as Mobilis is now transforming these prototypes into fully functional applications for real-world projects.