September 16, 2021

Optimal pile foundation design saves tons of CO2

Download the white paper and get INSPIRED

Learn how collaborative parametric design models allow you to work together for better solutions.

Optimizing foundation design

Voorbij created a web-based parametric design application on the VIKTOR platform to optimize the (re)design process of pile foundations, which helped their clients save a lot of time and money.

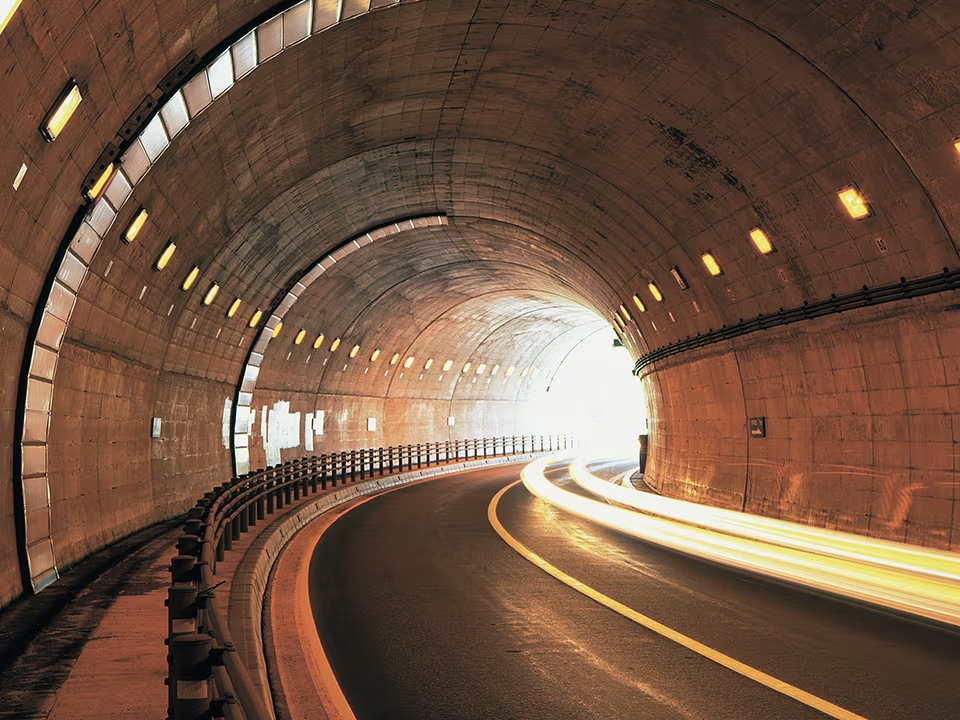

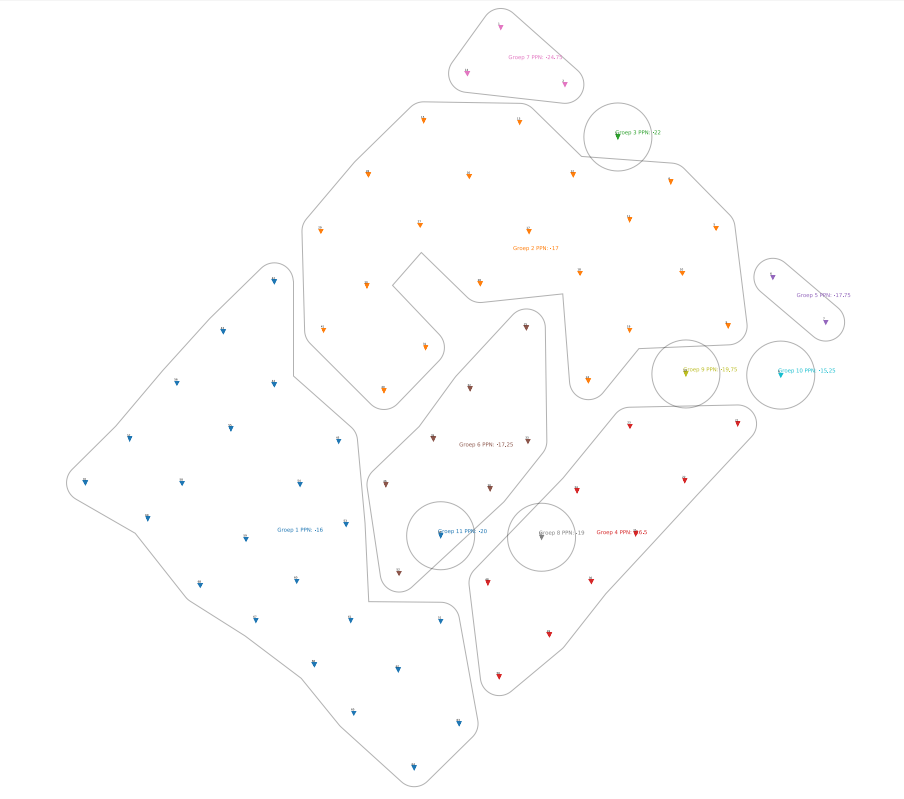

Map view of soil investigation

Before, Voorbij optimized pile foundations based on their experience, by grouping CPTs, and including soil variances in a smarter way.

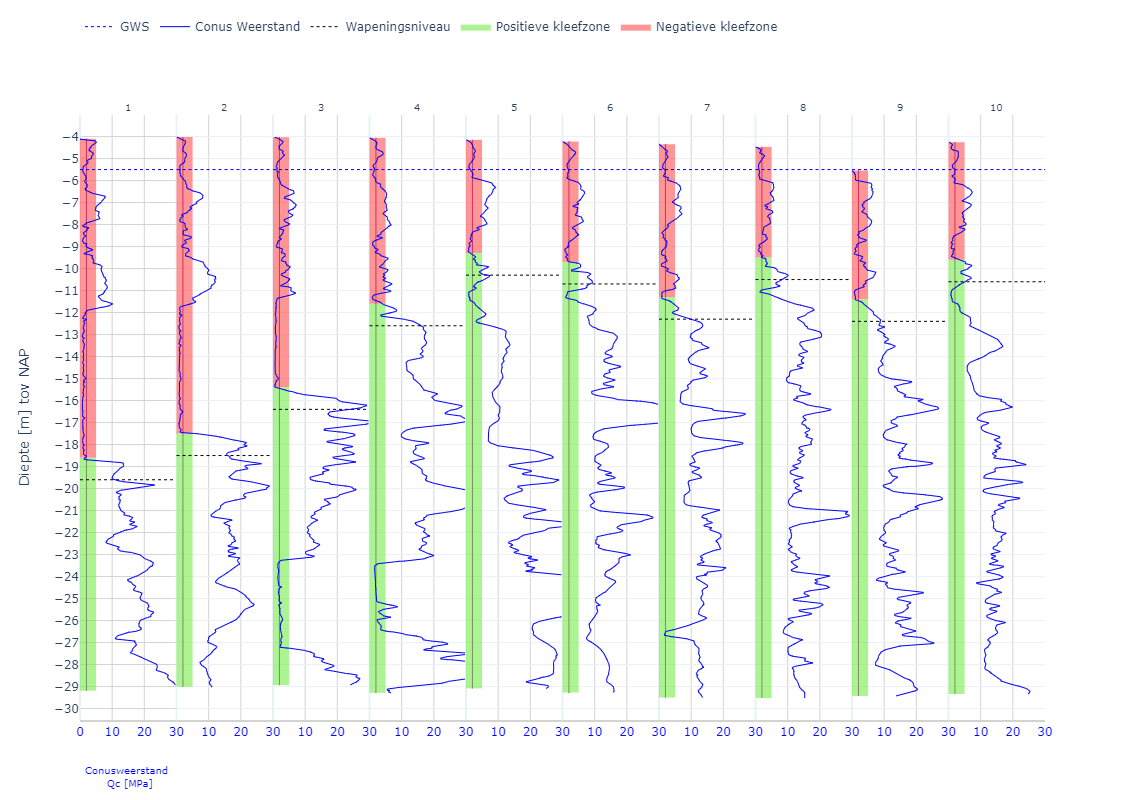

Soil interpretation of CPTs

Now, they use their application on the VIKTOR platform to speed up this time-consuming manual process. Their application allows for the automated grouping of CPTs based on a given set of rules and generates optimized pile plans according to aspects such as cost, soil structure, grouping, pile tip levels, and pile types. The app also provides Voorbij with rich visualizations of results for quick interpretations.

Visualization of calculation results

Using their own calculation core, Voorbij can indicate upper and lower limits of pile tip levels, easily generate designs, see interactive load-bearing charts, and visualize piles in combinations with the CPTs based on that information in their application.

Recently, Voorbij made a big update to their application, empowering their engineers to optimize even more parts of the process.

1. Load carrying capacity: The tool now supports calculations for both pressure-loaded and pull-loaded piles, which are essential in large-scale and construction pit projects. This expanded functionality allows Voorbij to take on a wider range of projects.

“With the application, we can now consider the whole construction pit integrally.” - Mark Remijnse, Head Sales at Voorbij Funderingstechniek

2. Cost calculation: The application now integrates cost calculation capabilities, helping engineers to align designs with budget constraints from the early stages of the project. This feature links design parameters directly to costs, allowing for more informed decision-making.

3. Work execution: To bridge the gap between design and execution, Voorbij incorporated logistical enhancements that streamline on-site construction. For example, the tool now supports the smart grouping of pile elements, optimizing material usage and reducing logistical errors. Additionally, it enables bulk material ordering based on the optimized design, further cutting unnecessary costs.

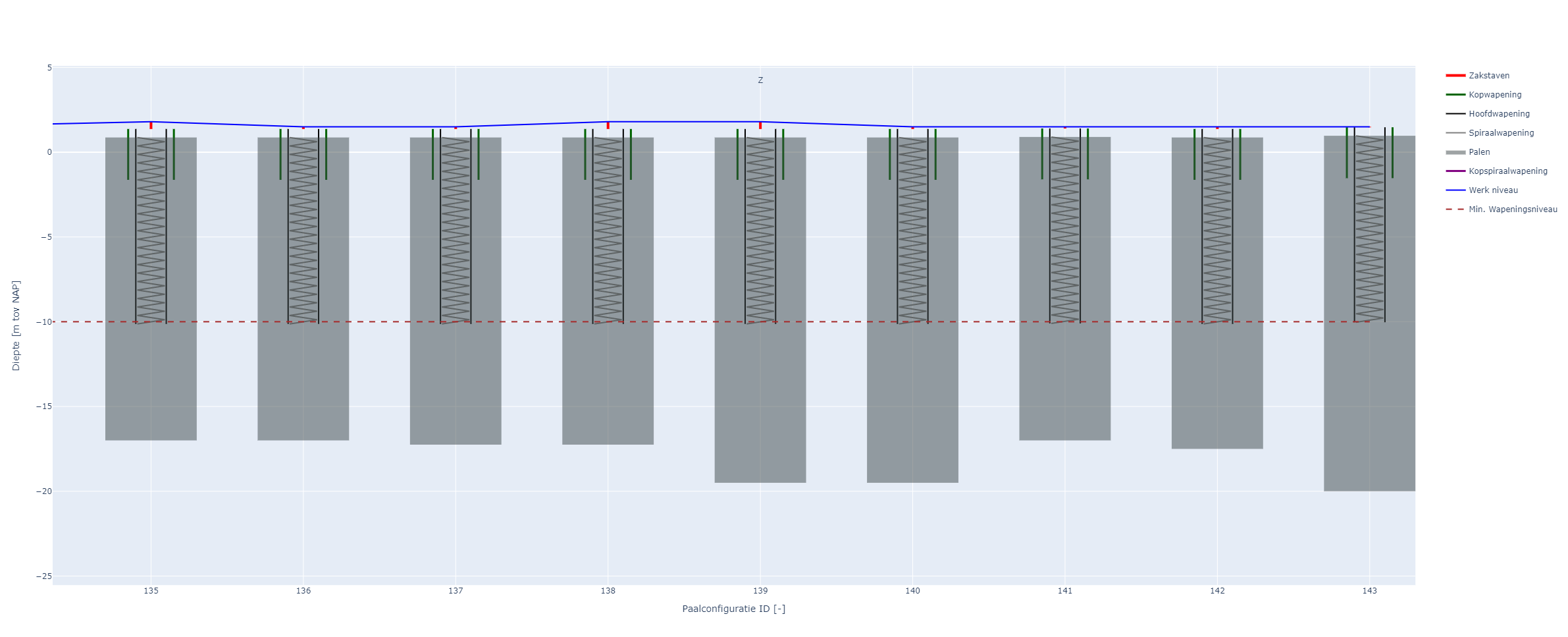

Visualization of combined pile rebar cages

4. Computational power: One of the most significant updates is the tool’s increased calculation capacity. Where the early versions could handle batch calculations of up to 150 CPTs, the latest version can now process up to 1,000 CPTs simultaneously. This dramatic improvement in computational power allows Voorbij to handle more complex projects faster and more efficiently.

Environmental benefits

Beyond the operational advantages, Voorbij’s application brings notable environmental benefits.

Reduction in crane days: By optimizing the execution process, Voorbij was able to reduce crane usage by 40 days in a recent project. This saved approximately 10,000 litres of fuel, directly reducing CO2 emissions.

Concrete savings: The application enabled the creation of a design that used 6,500 cubic meters less concrete compared to traditional methods. With every cubic meter of concrete containing 350 kg of cement, the design avoided the need for 2,275 tons of cement, which translates to a reduction of over 2,000 tons of CO2 emissions. Furthermore, it reduced the number of truck deliveries by 500, decreasing overall transportation-related emissions.

From engineer to advisor

Before adopting their automation tools, Voorbij was often tasked with translating definitive designs into executable ones. Now, with their parametric design applications, Voorbij’s engineers are involved much earlier in the project lifecycle, from the preliminary design phase onwards. This shift allows them to provide expert advice, optimize designs, and bring more value to the project.

"Thanks to our applications, engineers now spend only 4 to 8 hours on a design calculation, compared to 20 to 40 hours previously. This frees up time for more meaningful contributions." - Mark Remijnse, Head Sales at Voorbij Funderingstechniek

“Before, we were mostly doing calculations. Now we can put a lot of effort into advising. You can use your cleverness and really add value to a project this way.” – Wiebren Koers, Geotechnical Advisor at Voorbij Funderingstechniek

The BASE FT tool

Besides the pile foundation app, Voorbij has built several modules on the VIKTOR platform. At the core of their digital transformation is their BASE FT tool, a system comprising multiple applications, machines, and a database. This tool collects real-time data during construction projects, stores it in a centralized database, and applies data engineering techniques to refine future designs. By comparing past data, Voorbij is able to continuously improve project outcomes and predictions.

Future developments

Voorbij continues to refine its digital tools. Their next step is to introduce a nitrogen module into their pile foundation application, further enhancing its environmental performance. They also plan to leverage data from their BASE FT database to predict project timelines, analyze execution data, and improve future designs.

By merging expertise with cutting-edge technology, Voorbij is transforming traditional construction practices—saving time, money, and CO2 emissions along the way.

And see how you can build your own parametric design applications here.