Sign In

Download the white paper and get INSPIRED

Learn how collaborative parametric design models allow you to work together for better solutions.

Five years ago, I first came into contact with Geotechnics for a project to automate the design process of high-voltage pylon foundations (Wintrack). With a background in Aerospace, these are disciplines that are (literally) far apart. To be honest, I was also quite arrogant about it: "How complicated can it be to design a concrete foundation? Flying an airplane, that is really complex." Over the past five years I have learned a lot about Geotechnics, being involved in numerous projects from a parametric design perspective. As a result, that opinion has changed considerably and my love for Geotechnics has grown.

What is it that makes Geotechnical Engineering so interesting and challenging?

- Everything is unique, the soil structure is nowhere exactly the same.

- The behavior of soil is non-linear and heterogeneous: it is therefore labor-intensive to model properly.

- Unpredictability: you never know exactly what is underground and what its' properties are. You often only really find out how the soil behaves during the construction process.

Due to these circumstances, the greatest risks in construction projects often have to do with Geotechnics. Because everything is so different for each circumstance, Geotechnics does not seem to have the ideal conditions for automated/parametric design methods. Or does it?

Contents

In this article, I will explain why I believe that it is precisely because of the specific properties of Geotechnics that a lot can be achieved with the help of digitization. For this, the following will be discussed:

- The problem: Changes

- What is parametric design?

- How do you apply this in Geotechnics?

- What is the impact of these types of tools?

- Is there still room for human interpretation?

- How do you ensure that you can use this on projects?

- What is your contribution?

The problem: Changes

One of the major challenges during projects is that (many) changes occur along the way. The bigger the project, the greater its impact. The change can be caused by external factors, for example from changes in the desires of the customer or by new information from additional soil investigation. Often changes also simply occur because a design process does not run linearly but in parallel. During design processes, all kinds of different disciplines gather more information. This can lead to new insights and results in that the intended solution no longer works or that an opportunity is found for a better solution.

In order to mitigate this risk, the strategy is often chosen to record as much as possible as early as possible. We try very hard to ensure that no changes occur. “First time right” is a popular saying. But is this really possible? Isn’t progressive insight inherent in a complex design process? And don’t we miss a lot of opportunities for optimization if we record a lot too early on in a process?

I believe that you should turn it around: Make sure you organize your processes so that you can deal with changes correctly. Assume that the customer will come up with a change 20 times, the soil investigation will turn out differently, or that ideas will gradually arise to arrive at a more optimal design. This is where parametric design comes into play.

What is parametric design?

With parametric design, one quickly thinks of the parametric creation of a geometric model. For example, you can define a beam based on three parameters: length, width and height. For more complex constructions you can do this with more parameters. Besides geometric parameters, there are a lot of other parameters involved in a design as well. Think of soil parameters, loads, requirements, and preconditions.

By setting up a model parametrically, you ensure that when changing a parameter, the impact of this is immediately visible and transparent. This can be achieved by automating steps of the process.

An upside down force model of the Sagrada Família by Gaudí. The strings are weighted down and by changing the position of the weights or the length of the strings, the shape of each arch can be altered and the impact of this on the rest of the structure can be seen.

How do you apply this in Geotechnics?

Example: During a project, a geotechnical consultant made a large number of models to do settlement calculations for different cuts for a soil body. Gradually, additional soil research shows that the soil parameters are different than assumed. The geotechnical consultant now has to manually adjust all models and redetermine the required increase to meet the residual settlement requirement.

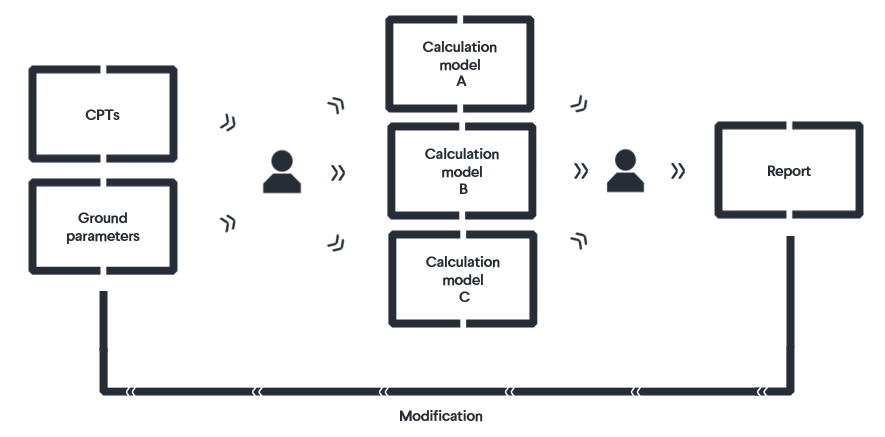

The traditional design process

The traditional design process

How can this be improved through parametric design, you may ask? Well, with parametric design methods you create one central place where the soil parameters are recorded. The geotechnical consultant now only has to adjust the parameter underwent a change, after which the models can be updated at just the push of a button. Subsequently, the required increment can be determined automatically, using a Python algorithm that iteratively makes several sums.

The parametric design process

The parametric design process

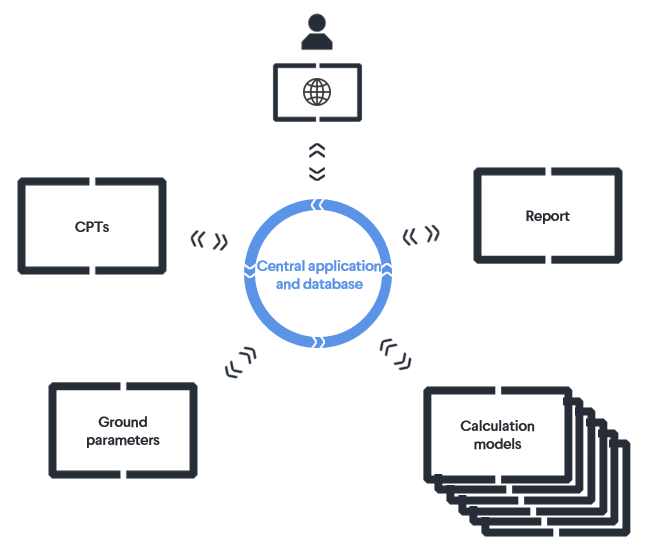

The principle of parametric design methods is quite simple: Centralize the input, link the various calculations and present the results clearly.

What is the impact of these types of tools?

With VIKTOR we have already developed many applications according to this principle, for example dikes, pile foundations, soil bodies, and sheet piling. These applications have now proven their value on all kinds of projects. Often links are made for this purpose with geotechnical software, such as the D-series or Plaxis.

The main results of the tools are:

- Time savings on “boring” work, which leaves more time to deploy expertise

- Flexibility with changes

- Risk reduction through more calculations, sensitivity analyzes, and less chance of errors

- Optimal design, because more iterations or cuts can be calculated

Is there still room for human interpretation?

I often notice that geotechnical consultants (like all engineers, by the way, apparently this is in our blood) are skeptical about automation. This is a very healthy and understandable response. Geotechnics is a field in which human interpretation and experience is essential: You do not put this knowledge into a computer or an algorithm. For example, the automatic interpretation of CPTs to a soil structure is very difficult to get right in 100% of the cases. It will not be possible to automate a geotechnical design process from A to Z in the foreseeable future.

Don't give up too quickly

I often notice that an idea for automation is being thrown off this. Because a few steps in the process cannot be automated, nothing is automated ultimately. That is a shame: You don’t go all the way from Rotterdam to Arnhem on foot because you have to change trains in Utrecht, right? Despite the time it takes to change trains, you are still 15 times fast in Arnhem compared to when you have to walk the whole distance.

Find the perfect balance

You can also look at a design process in this way. Where is the repetitive (“boring”) work essential? And where is human interpretation and expertise essential? The repetitive steps in the process often lend themselves very well to automation. A computer is very good at doing "stupid" (read: repetitive) work very quickly. Despite the fact that certain steps are still carried out by humans, you can speed up the process drastically.

When these types of tools are properly developed, it gives the consultant more insight, instead of becoming a black box. Consider, for example, the ability to perform sensitivity analyzes or to calculate many more cuts. Then the combination of people and computer ensures the strongest team in this situation as well.

How do you ensure that you can use this on projects?

Developing these types of applications of course takes time and money. Development time is often limited because a project has to be planned and follow a schedule. This makes developign an application for this challenging. The development initially requires an investment. Not only from developers, but also from a specialist who (in a Product Owner role) must give direction to the development. So, compared to the traditional design process, extra effort is required in the beginning. The role of the geotechnical consultant is also changing: They will develop part of their time, or work together with a developer to achieve a good application. The planning will have to be adapted to this process change. The involvement of the specialist in the development is also crucial to remove the black box feeling: The specialist understands what has been programmed and is able to explain it to others.

Of course, it also helps to ensure that you don’t start developing an application from scratch when a project starts. You can do this by developing more generic applications outside of projects that can then be used on different projects later. Also, by developing building blocks that you can quickly assemble or expand on a project.

Sharing applications

We have noticed that different parties require the same kind of applications for their projects. From this point of view, the initiative arose to develop tools together with various parties: The first application that was jointly developed for soil bodies. In this way, the investment is divided among different parties and the business case for automation is stronger!

Tools from VIKTOR

In addition, VIKTOR has taken the initiative to develop a number of basic tools for geotechnical consultants, under the name GeoTools. The first version of this was created based on input from various geotechnical consultants. With this application you can:

- Interpret CPTs to a soil structure with different methods

- Visualize these CPTs on a map and in 3D

- Define the soil parameters in a central place

- Create transverse and longitudinal profiles based on the CPTs

- Generate D-Series models based on the profiles and soil parameters

Other Geotechnical content

There is of course much more to be said about parametric design within geotechnical engineering. That is why we would like to take you further into the topic:

- Our colleague Roeland Weigand has written a blog about an improved filter algorithm that he has developed which enables geotechnical consultants to gain a better insight into the actual soil structure

- Together with Jacco Haasnoot (CRUX), Ritchie Vink (CEMS, sister of CRUX) and Rob van Putten (Waternet), I contributed to an article about digital building blocks in geotechnical engineering. By making domain knowledge accessible and smartly combining it with digital technology, we achieve better results faster!

- Kevin van Giessen has written a blog about the development and operation of the GeoTools application that was mentioned in this article.

We are looking for input!

We strive to be able to provide a valuable tool with the GeoTools, which makes the work of every geotechnical consultant easier and more fun. For this, we need input from specialists. So, if you are interested in the application, you can contact me directly via a personal message. I am also very curious about the experiences you have with parametric design and automation within geotechnics. If you have feedback, experiences or ideas, please send me an email: sjansen@viktor.ai.

See how you can create parametric design applications as well.