Download the White Paper and get INSPIRED

Find how you can use AI automate engineering processes in your organization.

Implementing AI within EPC

by Rimma Dzhusupova (McDermott)

Rimma Dzhusupova, leading the AI initiative at McDermott, delves into the application of AI within the EPC sector. While AI has found common use in the energy sector for tasks such as predictive maintenance and data analysis, its direct integration into engineering processes has been limited, especially in EPC organizations.

Recognizing this gap, McDermott started an AI team to develop internal AI-powered tools to automate repetitive tasks, enhance engineering designs, and improve project quality. Their primary goals are clear: reducing costs associated with engineering and construction projects and minimizing unnecessary resource losses, like materials and engineering hours.

Rimma presents two examples of the AI tool developed at McDermott to empower their engineers.

Identifying Design Errors with Image Recognition

During project development, engineers at McDermott create many drawings, and complex illustrations made through various software applications. Recognizing the risk of human errors in these drawings, being precise becomes essential to prevent disruptions in schedules, testing, and construction, ultimately mitigating significant financial losses. McDermott addressed this problem, for example, in valve drawings in pipeline systems. They developed a tool using deep learning, creating a model capable of distinguishing correct and incorrect representations of patterns within drawings. To be able to detect the errors, McDermott created a state-of-the-art training database, encompassing diverse patterns and potential errors. This database was instrumental in training the model to identify mistakes with a high level of precision.

For a visual demonstration of design error detection, you can go to min 7:05 in the recording.

Material Quantity Estimation with Image Recognition

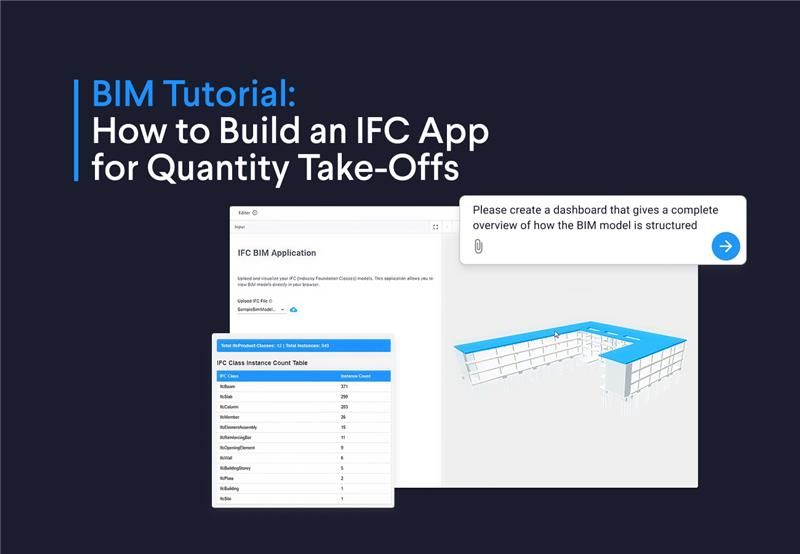

Rimma also discusses material quantity estimation, a traditionally time-consuming task in the industry. When no computer-aided files are available (for example, during the tender phase of the project when only PDF drawings are shared with potential EPC contractor), the only method for estimating material quantity and then project costs involves manually counting the symbols in the drawings, transcribing the data into spreadsheets, and extracting information and text— a process that could span days, weeks, or even months. To optimize this process, McDermott devised an algorithm grounded in object recognition, symbol recognition, and text recognition, that can autonomously extract information from the drawings, significantly reducing the time and effort needed for the estimation. The approach they adopted works on a "what you see is what you get" principle, basically focusing on the importance of extracting information directly from the visual data. To enhance the accuracy of their estimations, McDermott uses its historical database, incorporating information on previous projects to make highly precise predictions of future material spending.

The tool combines deep learning techniques and simple regression which is based on robust data management that ultimately helps estimate the materials spending within hours! You can follow the visualization of this process at min 13:21.

Augmenting Structural Analysis with Programming and AI

by Doğukan Karataş (Dlubal)

Dlubal Software is actively working to bridge the gap between structural analysis and design. Their mission is to drive technological innovations within the construction industry.

Integration of AI to maximize value

Dlubal has been incorporating artificial intelligence into its software products for some time. One example is the integration of AI in RFEM, where a tool has been developed to optimize costs and estimate CO2 emissions. This tool identifies suitable parameters for parameterized models or blocks by adhering to standard optimization criteria.

Talking about the ongoing effort to integrate AI, Doğukan introduces their new AI tool "InApp Help ChatBot", which originated from the idea of leveraging Dlubal's extensive help and support documentation. They trained a language model using a rich dataset accumulated over two decades of active customer support, incorporating valuable contributions from engineers, including FAQs, knowledge-based articles, and also webinar scripts. They now want to employ this data in creating a neural network and serve their users non-stop inside the program. The goal is not just to construct a basic question and answer platform, but to develop an AI-driven assistant that empowers users to maximize the value derived from Dlubal's programs!

Natural language processing to create models

Text2Model is an interface that allows users to describe the model they would like to have, and the advanced natural language process creates the model accordingly. Dlubal-trained AI model extracts valuable data from natural language input and it finds and categorizes the key entities such as location, material, section, and all other specialized terms for the user prompts. They called this process "Entity Recognition". Then the extracted parameters are used in a template Python script, and transmitted via the API to RFEM, initiating the creation of the specified model.

Dlubal envisions the future to have a generative AI directly integrated into the program, allowing users to mention anything within the software and generate corresponding models. If you are curious to learn more about this tool you can go to min 13:48

Watch the full presentation to discover more about AI at Dlubal

CORE studio: Accelerating Ideas to Applications

by Robert K. Otani, PE (Thornton-Tomasetti CORE studio)

CORE Studio is a specialized group within the broader Thornton Tomasetti engineering consulting firm. Its mission is to provide advanced computational design, engineering, and application development services. CORE Studio's ambitious goal extends beyond its immediate functions; it aspires to lead the entire company forward through continuous R&D efforts.

Innovation, community, and transparency

Beyond its internal functions, CORE Studio actively engages with the larger architectural and engineering community. Since 2013, the studio has been hosting AEC Tech events, fostering open discussions on the evolving technological landscape within the industry.

Their vision of fostering innovation through community and transparency is well represented in their R&D program, described below.

R&D to solve industry challenges

The R&D program at CORE Studio is an inclusive initiative designed to foster innovation across the firm and broadly to the industry. The program operates on a firm-wide scale, securing funding for many projects throughout the year. CORE Studio adopts a unique approach inspired by Innovation Tournaments (1) and sees the participation of 30 individuals for each event. A key highlight of this approach is its inclusivity, encouraging input from diverse corners of the firm. The process begins with idea creation, where participants submit ideas and peers vote on projects, with no influence from organizational leaders. Selected projects are developed further, with the potential for securing funding. The process follows the "quad charts" to articulate the idea, the pathway to realization, business plans, projected ROI, and resource/funding needs.

The selection of ideas is a completely peer-driven process so that individuals on the ground prioritize what they collectively consider crucial for advancing the firm's technological capabilities to address industry challenges. In the CORE Studio R&D program, the spectrum of ideas ranges from incremental improvements addressing daily challenges to more transformative concepts.

If you want to discover more about the R&D process you can watch it at min 08:40 of Robert's presentation.

Next are some examples of ideas translated into software at CORE Studio.

Tekla automation and optimization

At CORE Studio, they developed a whole suite of automation tools. Go to min 12:45 or continue reading to discover more about them.

Auto Connect

The Tekla automation suite stands out, featuring tools like "Auto Connect." This tool is designed to streamline and speed up creating connections in a Tekla model. By using the data attributes of forces within the model, this tool transforms an unconnected Tekla model into a fabrication-ready structure with just a few clicks. Users can select bolt types, connection types, and shear connection types, with the capability to apply these changes to an entire building if desired.

Auto Checker

Another tool is the "Auto Checker", a tool that examines elements in the model that have not been verified or have undergone changes throughout the process. Particularly crucial in the fabrication stage, this automated checking process ensures the accuracy and integrity of the model before going ahead to the final steps.

They called this tool of Tekla Auto Checker the "Tekla Listener," because its role in not just automating tasks but also actively checking and responding to changes in the model. What would traditionally take a manual effort of possibly a day's worth of work can now be achieved 10 to 100 times faster through these automation tools!

Sustainable and decarbonization with Revit

Spotlight is a material takeoff and data visualization tool designed to promote sustainable, decarbonized design and construction practices. Operating as a Revit application, Spotlight generates web visualizations, simplifying the complex process of visualizing materials and system quantities within a project. Additionally, being a web interface, Spotlight helps share insights so that project managers and clients can easily access visualized data, fostering a collaborative approach to decision-making.

Go back to min 15:32 to hear more about the impact of Spotlight.

*1. Reference: “The Innovation Tournament Handbook” by Christian Terwieschk and Karl Urlich.

Start building apps for free

Related Blog Posts

Get our best content in your inbox

Subscribe to our newsletter and get the latest industry insights