Download the White Paper and get INSPIRED

Learn about trends in digital transformation and how they affect the engineering and construction industry.

“It can save a lot of engineering time and money for the entire industry and helps to distribute knowledge more efficiently to our customers,” explains Jelle van de Ridder, R&D engineer at C-Job. "In the offshore sector a lot of repetitive tasks are done that need to be automated so that our engineers have time to focus on the creative processes".

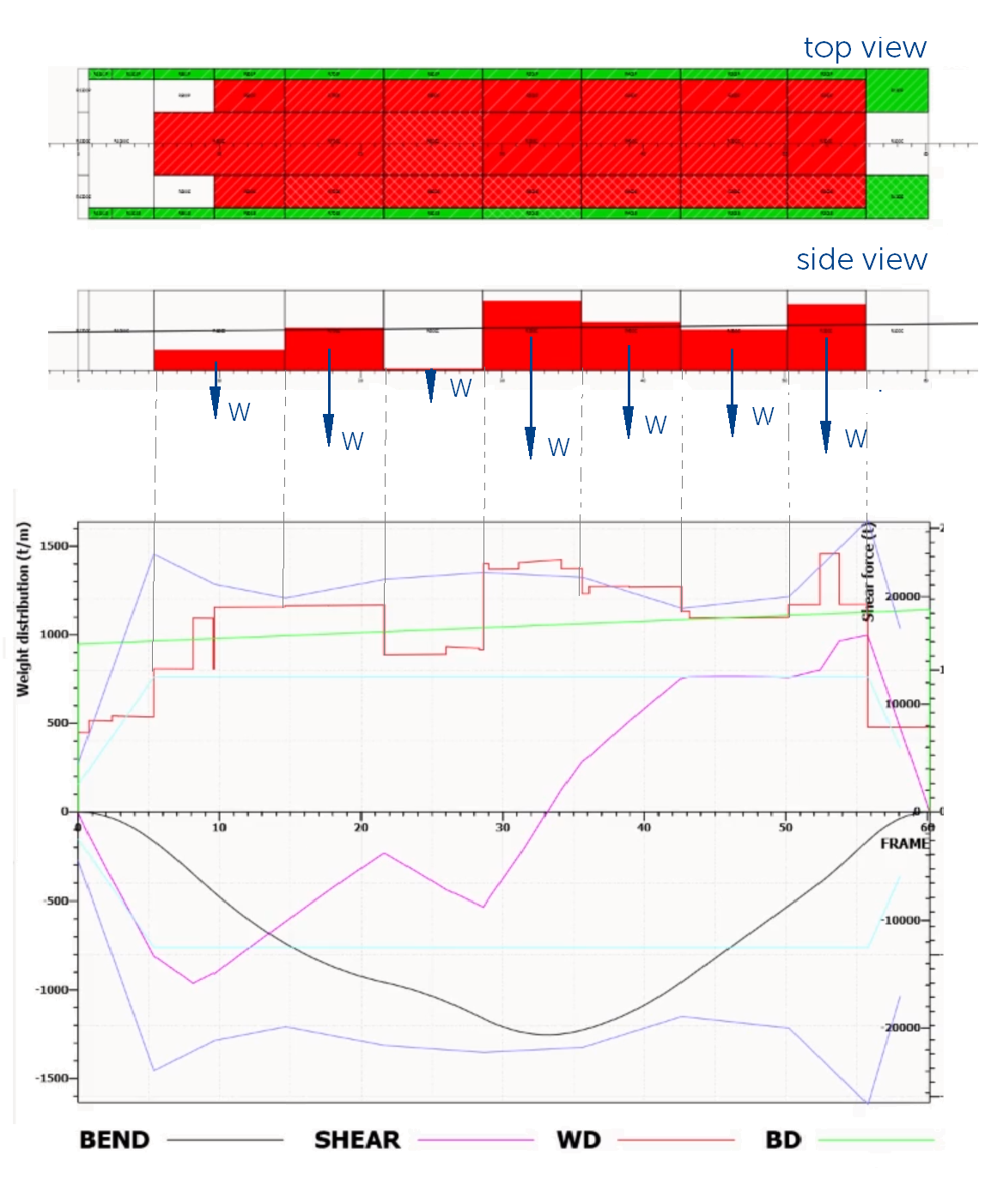

Cargo distribution tool

At C-Job they build a 3D model of a ship in NAPA. There they can perform stability and strength calculations on this ship with different amounts of oil and water ballast in the tanks. “The combination of the cargo in the tanks affects where the center of gravity is, and it affects how your ship bends.” Van de Ridder explains. Together with VIKTOR, they are building an application that tests many different load combinations and determines the strength, stability and damage stability of each combination. “In the past, an experienced lead engineer made a rough estimate and tried out 10 combinations by hand. The application can do 300 iterations within an hour. ”, Van de Ridder. With the help of the application, they can find the optimal load distribution, in which they can fill up as much crude oil as possible. “The amount of oil is ultimately the most important factor.”

Knowledge distribution

Van de Ridder: “The biggest challenge was sharing our knowledge without losing our business proposition.” In the developed tool they were able to digitize the specific knowledge of C-Job in an application, where the client could only see the results. In practice, this means that the customers of C-Job can generate an optimal load distribution via the web-based application in an easy and cheaper way. “This is also beneficial for our engineers as they no longer have to perform this calculation manually and can concentrate on the creative part of their work.”

The results of an application are immediately visible. Jelle van de Ridder, R&D Engineer at C-Job: “Every time they changed the layout of a ship, all calculations of the load distribution had to be done again. This was done manually and can take weeks for an engineer. “now they can reduce this computation time to just a few hours.

Future of web-based applications

C-Job sees opportunities in more web-based applications. Van de Ridder: “Our tool now determines the optimal distribution of liquid cargo on a ship. “We also like to develop further, for example by combining the load optimizer with the crane polar plot tool. With this tool we answer the question from a ship operator: “Can I lift this load at this position, or what do I have to change to lift this load?” It can be useful to optimise a load for a particular crane operation.

The time and money it takes to develop an application is quickly recouped by the engineering time and money saved by performing manual calculations by engineers. If there is a well-defined problem statement in which a repetitive element is present, it is worth looking for automation options.

Visualization of the calculations of the optimal distribution of liquid cargo on the ship in the web-based application

Visualization of the calculations of the optimal distribution of liquid cargo on the ship in the web-based application