Sign In

February 28, 2023

New ship design tool reduces lead time up to 50%

by C-Job Naval Architects

Download the White Paper and get INSPIRED

Learn about trends in digital transformation and how they affect the engineering and construction industry.

In the early phases of a design, engineers are forced to make decisions that can have an irreversible impact on later design stages. Due to limited time and data, these design decisions are never optimal. This leads, for example, to ships with higher building and operational costs than actually needed. Especially with regard to current sustainability ambitions and economic conditions, this problem has become more and more relevant to date.

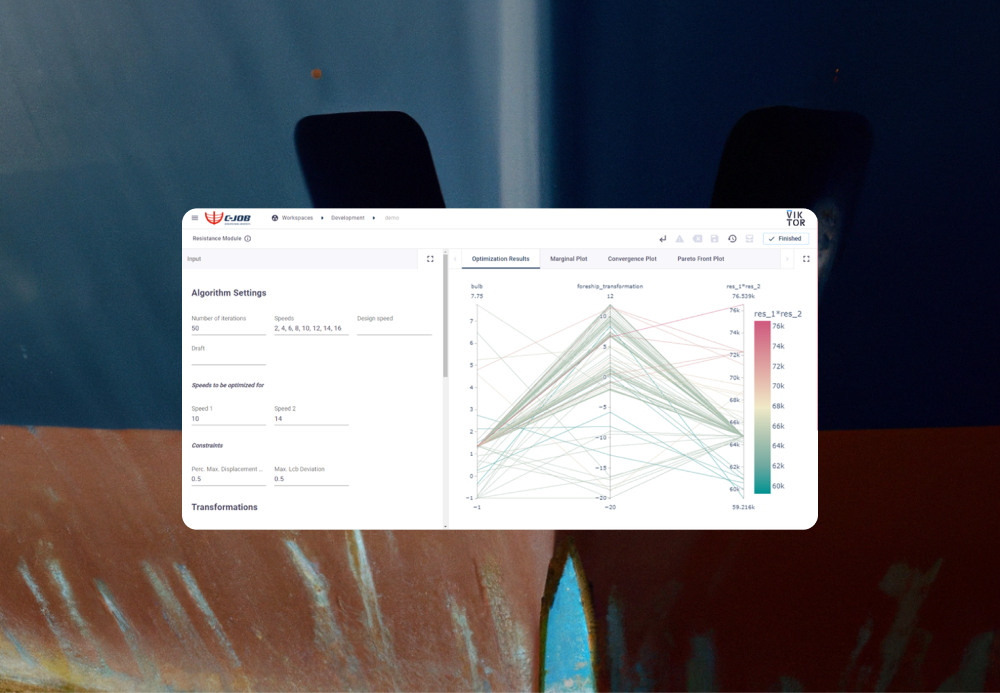

Roy de Winter, R&D Engineer at C-Job Naval Architects, says “That is why it's important to find a way to make these decisions in a data-driven way. An optimization process is difficult and labor-intensive but very essential to ensure reliable and efficient results. Together with the VIKTOR platform, we were able to create a web app , the ACD resistance module, that optimizes this process and reduces building and operational costs.” With the ACD resistance module, a ship’s hull is optimized based on its resistance, which in turn will result in superior building costs (CAPEX) and operational costs (OPEX) for ship owners. Together, this creates a ship design that ensures the delivery of the highest design quality in the shortest amount of time: up to two times faster than before. With the web app, chances of having to make any changes later in the process based on key decisions made earlier in the design are reduced to almost zero, resulting in an overall smoother process of the whole ship design. The two companies were a perfect match for the creation of this web app. With C-Job's experience in R&D, data science, and coding, the company knew exactly what input was needed. As a software company with engineering DNA, VIKTOR helped them bring C-Job's vision to life with their team of developing engineers that offer expertise and co-development throughout the process of turning the idea into a usable web app with Python.

Roy continues “Working together with VIKTOR, we were able to build an easy-to-use web app that combines all our knowledge into a one-stop cloud-based solution for our engineers. The creation of the web app could not have happened without VIKTOR, they were essential to making the ACD Resistance Module what it is today.”

Wouter Riedijk, CEO and co-founder of VIKTOR, says “We strive to never stop exploring new ideas and technologies and were excited to collaborate with C-Job on a solution that helps unlock engineering potential to an exponential degree. Through the VIKTOR interface, engineers can turn any idea into a cloud-based, interactive, user-friendly, that is accessible to anyone.”

The ACD Resistance Module operates via the VIKTOR platform which offers a user-friendly interface where multiple users can work on projects. VIKTOR takes care of the UI, while C-Job's domain knowledge is running behind the scenes.

To find out more about the web app and other work by C-Job and VIKTOR, please visit www.c-job.com or www.viktor.ai