September 21, 2021

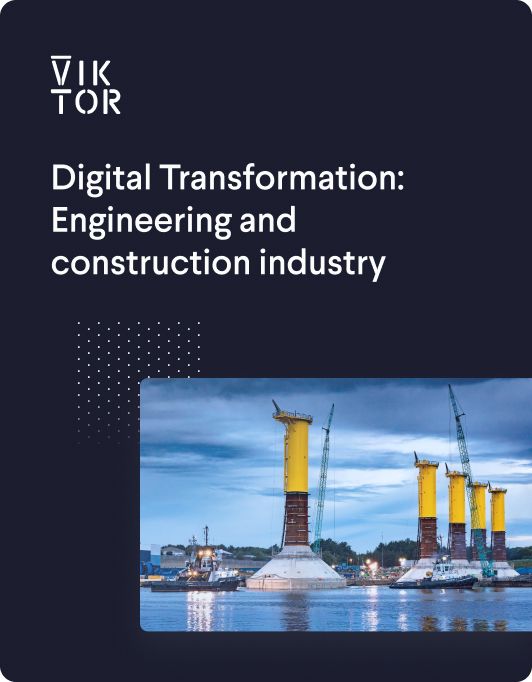

Digital Transformation in Engineering and Construction

by Peter Madlener

Download the White Paper and get INSPIRED

Learn about trends in digital transformation and how they affect the engineering and construction industry.

20 years ago, I, Peter Madlener, started working at the age of 16 as a welder at a heat exchanger manufacturing company. Now, when I walk into a workshop, engineering department, or a jobsite I am still amazed that processes are not much different from back then. This is especially remarkable when considering that I just got out of my car which could drive autonomously and in my pocket is a mobile phone which has enough processing power to send a rocket to the moon.

What is keeping engineering and construction companies from implementing widely available technology to accelerate their digital transformation? Fascinated with this subject, I joined forces with Max Breeman who is doing a master's in management of Technology at the Delft University of Technology. During his studies, he has worked for several technology firms and has developed a keen interest in the struggle of ICT adoption within engineering. Together, we interviewed numerous industry visionaries to answer these questions and we gained many insights, some of which I will share with you here.

E&C: A great and important industry

The importance of the engineering and construction industry is obvious. The industry is responsible for building our infrastructure, our industrial facilities, and the places we live. It is one of the biggest industries in the world. According to the U.S. Census Bureau, construction spending in 2019 topped $1.3 trillion in the USA alone. Despite the Covid crisis, the industry is currently growing at a rapid pace with an expected growth of 3% in 2021. This trend of a growing demand for engineering and construction projects will continue over the next few decades: Estimates show that only 25% of the infrastructure we will need 2050 is already in existence today.

Demand

To keep up with demand while also staying competitive, E&C companies feel a sense of urgency to invest in new digital solutions that help with their workload. At the same time, the E&C industry is one of the least digitized industries in the world, with the shift towards digital still in its early stages. The introduction of digital solutions to the work floor could create huge potential, provided the people working with it are able to extract the right value from it.

Supply

On the supply side, digital product and service companies see this as an opportunity resulting in an overwhelming influx of digital solutions and ICT consultancies. The gap between what is available and what is currently in use throughout the industry keeps growing. This can make it daunting to start introducing these kinds of technologies, since they keep getting more advanced with each release. Thus, harder to adopt for people that are unfamiliar with their workings. If you want to start now, this leaves the question: Where do you even begin?

Connected systems, intelligent machines, IoT and new software applications designed to support the engineering and construction processes all offer great promise. But you can’t implement them all at the same time. The huge difference in supply and demand makes it even more important to carefully take the right steps at the right time in this process of transformation. To do this, it is important to really focus on the ‘why’ of this transition. What is it that we want, exactly? What processes do we want to digitize? What tools do employees desire? And how will we gain (and measure) return on our investment?

Digital transformation in E&C

The main challenge in a digital transformation is not the technology itself, as the supply of these technologies is overwhelming, but rather convincing your people. Transformation processes are always 80% human and just 20% technology. Since many companies have already implemented the necessary technological innovations before, there is no reason to reinvent the wheel. Instead, focus should be on the challenges regarding people and processes within your digital transformation.

People

There are many digitization related changes that are currently going on in the E&C industry, such as the rapid influx of digital technology in the lives of employees and an ongoing labour shortage. Additionally, there is a separation between two generations of employees. New workers are more technology centric, meaning that the need for better and more advanced work-related digital technologies has been rising and will continue to rise over the upcoming years, widening the gap between non-tech-savvy and tech-savvy people.

Process

A typical engineering and construction project involves not only multiple companies, but also different departments within a company. The brief time a team spends working on a project is usually too short to have an incentive to embrace new (digital) methods. When you have a job to do, it is easier to use the methods you are familiar with than to develop a new one of which you don’t know if it will work in advance. Moreover, projects in the E&C industry vary greatly, which makes construction companies struggle to implement digital tools that can be applied on multiple projects. And, next to uncertainty about reusability, there is also a battle for the limited R&D budgets within the construction industry, especially compared to other sectors, like aerospace or automotive.

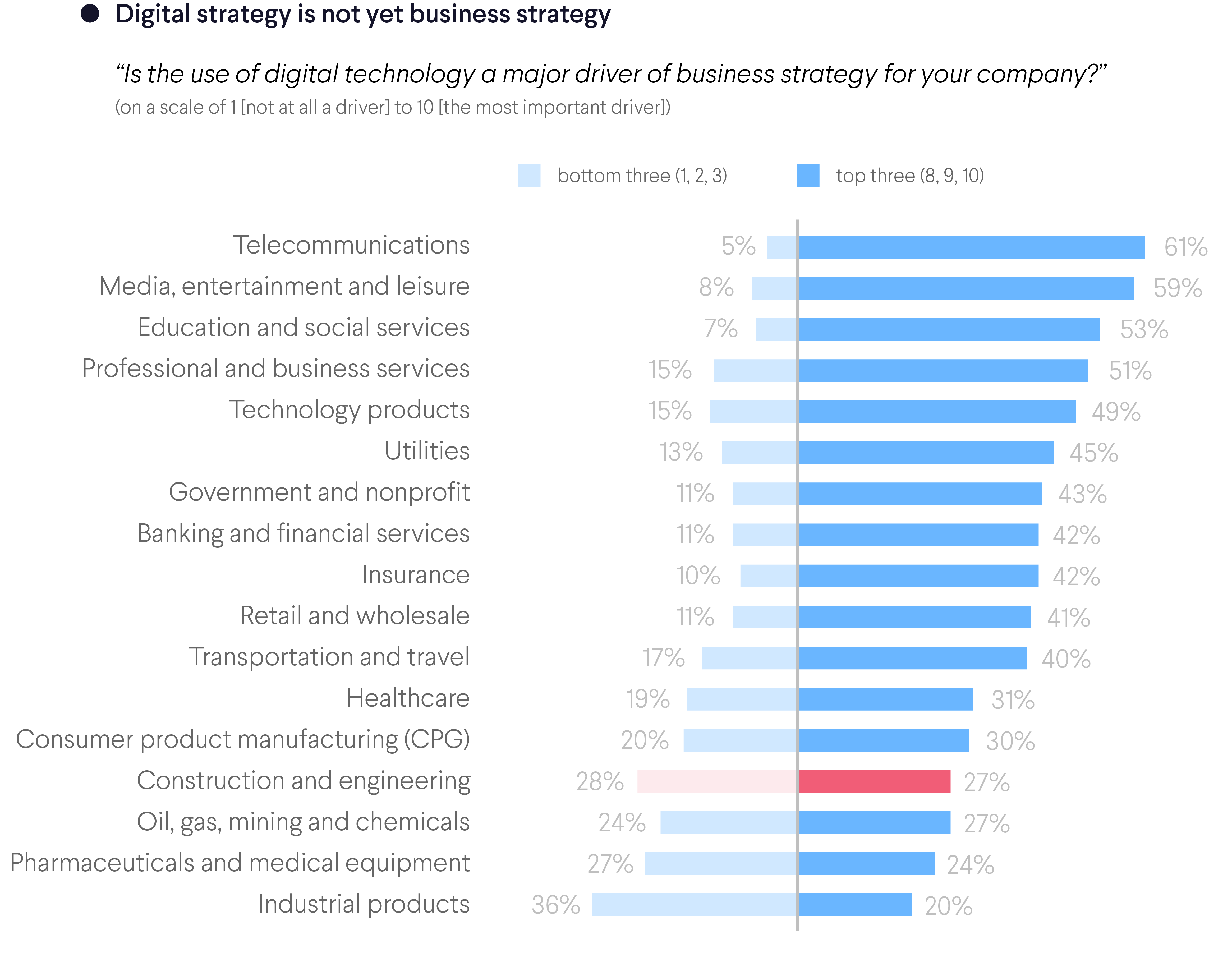

Use of digital technologies per sector in %

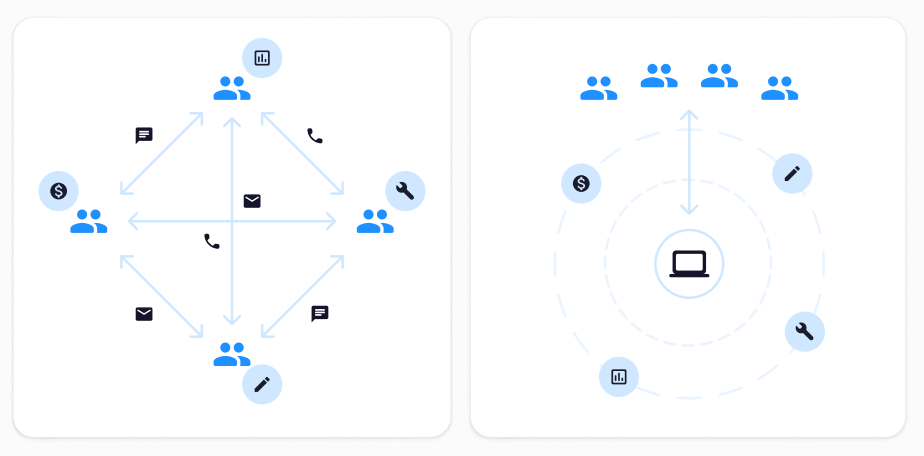

This results in departments that keep on doing their own part of the implementation, with poorly structured communications between departments. Information sharing is slow and haphazard, resulting in different versions of reality. Digital transformation can solve this problem and, at the same time, help to capture and analyse data more effectively and more efficiently.

The impact of digital solutions on multidisciplinary communication: scattered (left) vs centred (right)

What should the digital transformation look like?

So how could the digital transformation help relieve the pressure on the industry? Digital technology holds much untapped promise for improving the E&C industry. The digitization of workflows is a good place to start. But what should a digital transformation look like? We tried to formalize this in four steps, which iterate continuously rather than as one-time actions.

1. Matching technology to process

The first step is proper matching, both with people and process. You need to match new digital technologies not only with the current workflow you want to digitize, but you must also take the human aspect into account. Within a firm this match usually has two points of origin. One is top-down, where management introduces a new technology. The other is bottom up, where an employee (for example an engineer) introduces a new tool within the workflow. This matching should not only be done internally, but also with an external focus. Many E&C companies employ contractors who will be working with the tool, or customers who want to view information about the status of a project, so it should be workable for them as well.

2. Create new job aspects

The second step is one of creating new job aspects. If you introduce a digital solution to the workflow, the engineer who helped to introduce it, is also the one that takes care of it. This adds a whole new aspect to their engineering job by becoming a bit of a programmer as well, part of the time.

3. Introduce a new value mindset

With this shift to also being part programmer and product owner of the digital product, the engineer just helped with building a new mindset for value creation. Where the conventional engineering process delivers value in a linear fashion, a digital way of working often does not. In classical engineering, every step adds value. With programming, the initial steps usually lay down the groundwork. Value is created, usually exponentially, at the end of development. Because results are not immediately visible, it is important to make sure this process is understood throughout your organization.

4. Process changes

By introducing a digital solution to the workflow, data can be centralized and democratized. Information becomes more accessible for everyone in the organization, which fundamentally changes the way E&C firms work. From this centralization, new ideas and tools are enabled to grow. Additionally, since the value delivery process is not linear anymore, new ways of working will be needed, such as Scrum. Because the focus also shifts from linear value creation to measuring exponential outcomes of the tool developed, companies need to start thinking about maximizing return on investment from their digitization efforts as well.

Opportunities

The engineering and construction industry is one of significant long-term costs and low margins. Transforming project initiation, such as the design process, financing, and procurement can yield a 10 to 30% reduction in engineering hours. This can, for example, be achieved using generative design. Within the construction process itself, a 5 to 10% reduction in building cost can be achieved through the implementation of Building Information Modelling (BIM) as well. And when a project is finished, a 10 to 20% reduction in operations and asset management cost can be achieved by continuously using this BIM system too. The digital transition of an E&C company could even aide in decommissioning, as a more efficient process could reduce the decommissioning hours between 5 to 10%.

Ways to realize value from investing in new technologies within the E&C industry

By implementing technological advancements, you can improve your bottom line and make better use of the resources you have, distinguish yourself from the competition, and gain a competitive advantage.

This is the first in a series of blog posts about the digital transformation within the engineering and construction industry. Following articles will dive deeper into the available technologies, the problems engineering companies face, processes, solutions and more. We will talk about how you can make professional engineering solutions that everyone can use, as well as on how you can build parametric design tools using Python and common engineering software like Grasshopper, Dynamo, SCIA, RFEM and IDEA StatiCa.

Want to know exactly what you need to get the digital transformation of your E&C company going? Download our whitepaper now!

Download the White Paper and get INSPIRED

Learn about trends in digital transformation and how they affect the engineering and construction industry.